Introcution to this webpage

Strength of Materials, often termed also as Mechanics of Materials, is generally the name applied to a discipline in which the stress, strain and deflections of loaded structural elements are considered. To be more specific, it is the physical science that examines the distribution of internal forces of a solid body, typically a prismatic bar, due to mechanical and thermal loads and the body's reaction to deformation.

This Strength of Materials Virtual Laboratory presents the laboratory aspects of this subject, in an imaginary way. It is intended to give an experimental understanding and verification of the coursework covered in Strength of Materials. Students will have the opportunity to review the theory, appreciate the fundamental hypotheses and clarify the deformation modes of a prismatic bar by watching animated pictures. Animations present experimental tests on different materials in tension, compression, torsion, bending, shear, buckling, and some combinations of them. By watching the provided tests, students get a near-realistic feel of the experiment, which in turn help them to understand the theory, and compare the experimental results with handbook values. A short quiz is provided at the end of the each lab to test the understanding of students, followed by a list of further reading topics on the subject matter.

However, it should always be kept in mind that this virtual laboratory is not intended to replace the real experiments. It is designed to give those who have difficulty to access real experiments a simulated experimental environment. Naturally, many factors such as the operation of equipment and discussion of unexpected results cannot be reflected.

Mechanical Testing

Because of the need to compare measured properties and performance on a common basis, users and producers of engineering materials use standardized test methods such as those developed by ASTM and ISO. These standards prescribe the method by which the test specimen will be prepared and tested, as well as how the test results will be analyzed and reported.

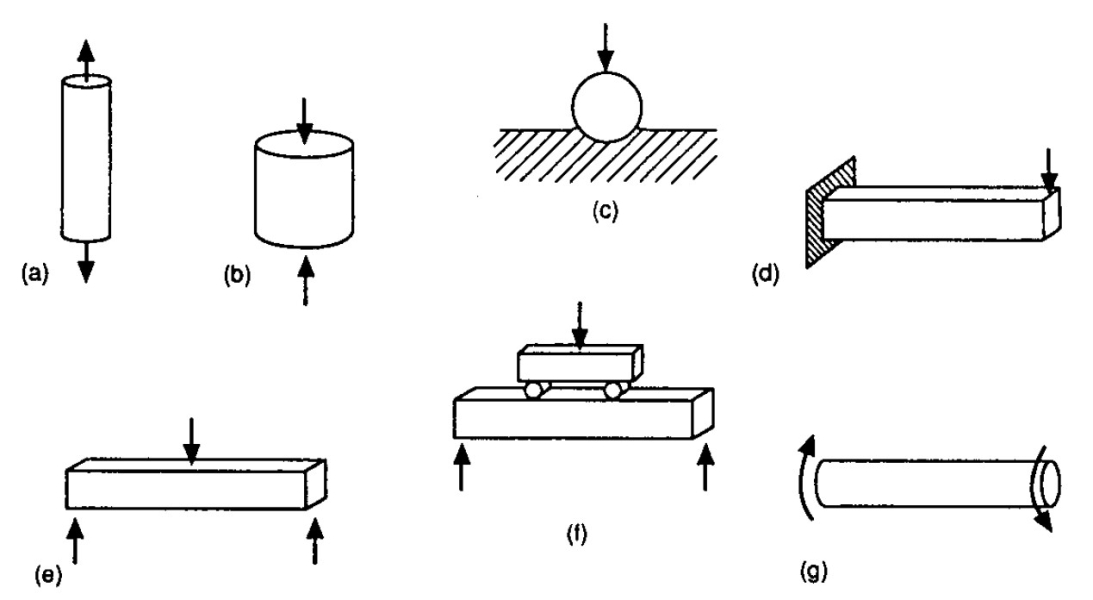

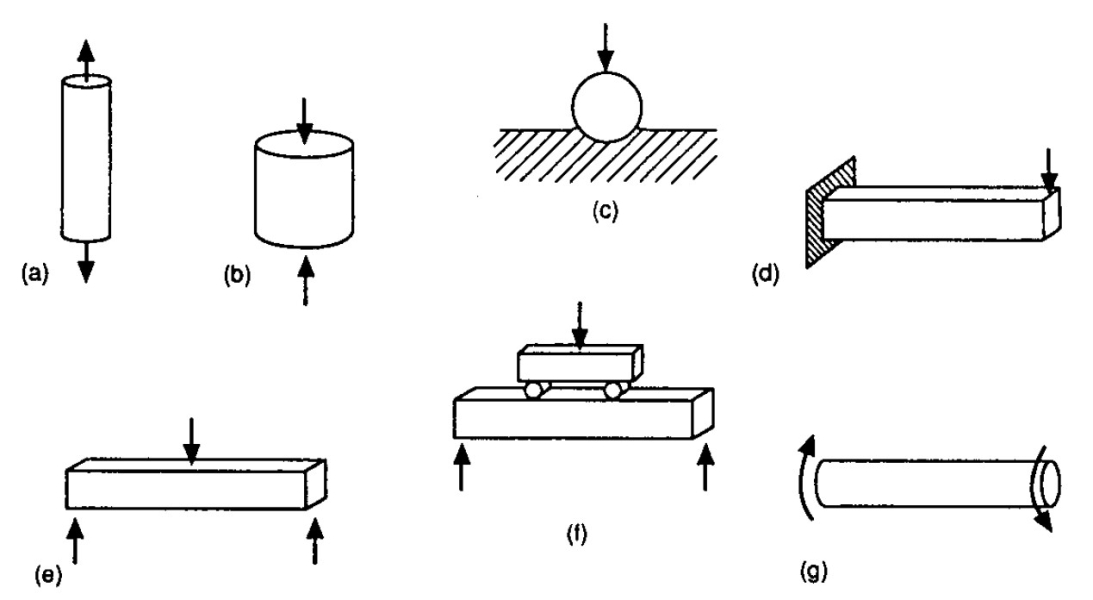

Mechanical tests often involve the deformation or breakage of samples of material. Some common forms of test specimens and loading situations are shown below: a) tension, b) compression, c) indentation hardness, d) cantilever flexure, e) three-point flexure, f) four-point flexure and g) torsion. Note that test specimens are often nothing more than specialized engineering components in which a known stress or strain state is applied and the material properties are inferred from the resulting mechanical response. A strength parameter is nothing more than a stress “at which something happens”, i.e. the onset of nonlinearity in the stress-strain response for yield strength, the maximum applied stress for ultimate tensile strength, or the stress at which specimen actually breaks for the fracture strength.

Design of a test specimen is not a trivial matter. However, the simplest test specimens are smooth and unnotched. More complex geometries can be used to produce conditions resembling those in actual engineering components. Notches that have a definite radius may be machined in specimens. Sharp notches that produce behaviour similar to cracks can also be used, in addition to actual cracks that are introduced in the specimen prior to testing.

Equipment used for mechanical testing range from simple, hand-actuated devices to complex, servo-hydraulic systems controlled through computer interfaces. Common configurations involve the use of a general purpose device called a universal testing machine. Digital, closed loop control over force, displacement, or strain along with computer interfaces and user friendly software are common. Various types of sensors are used to monitor or control force, displacement, or strain. In addition, controlled environments can also be applied through self-contained furnaces, vacuum chambers, or cryogenic apparatus. Depending on the information required, the universal test machine can be configured to provide the control, feedback, and test conditions unique to that application.