Southeast University has long been engaged in intelligent disaster prevention research on infrastructures, and carried out systematic laboratory hardware conditions construction, scientific research site planning and supporting facilities construction, and has built earthquake disaster laboratory, structure component fire resistance laboratory, explosion impact laboratory, etc.

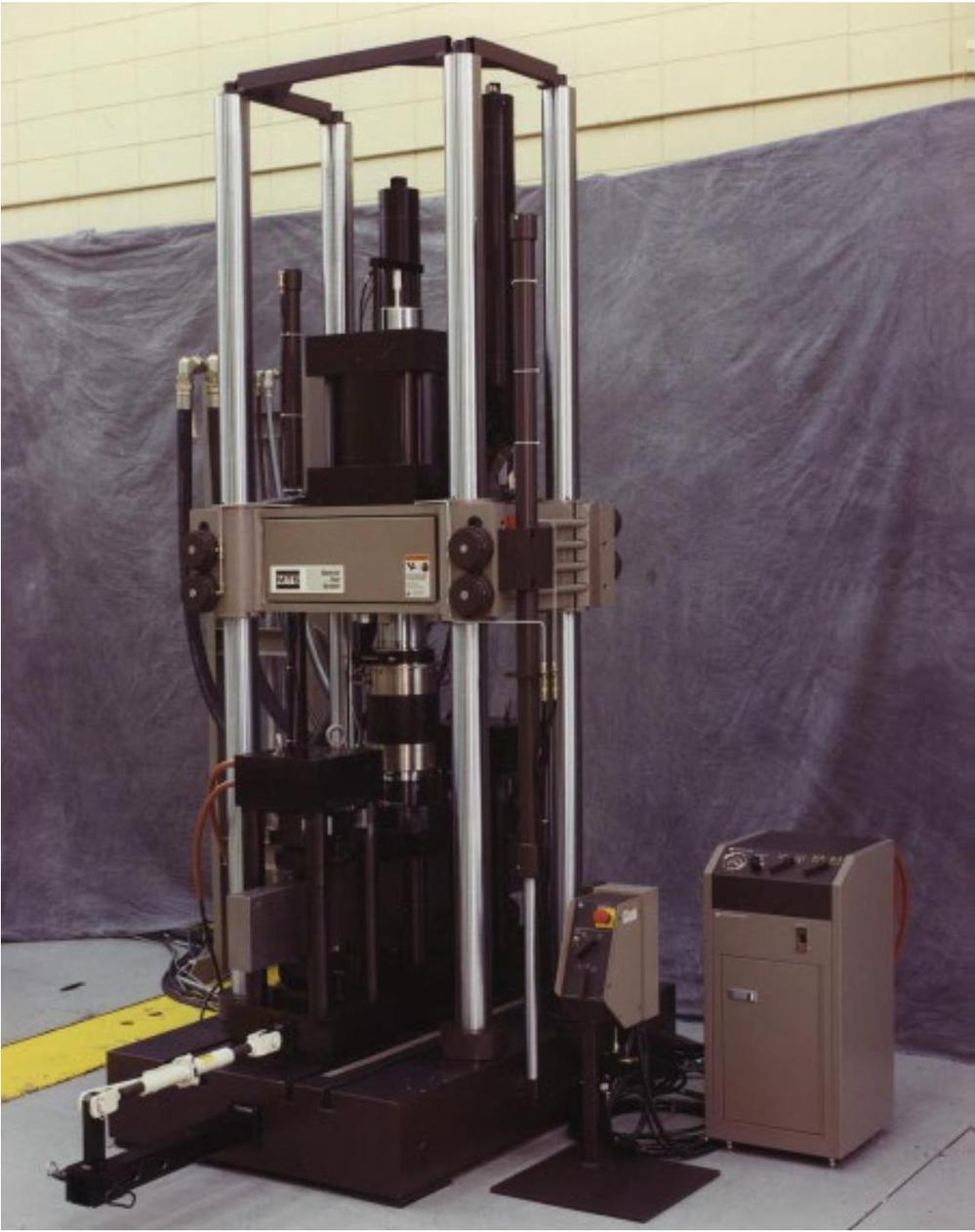

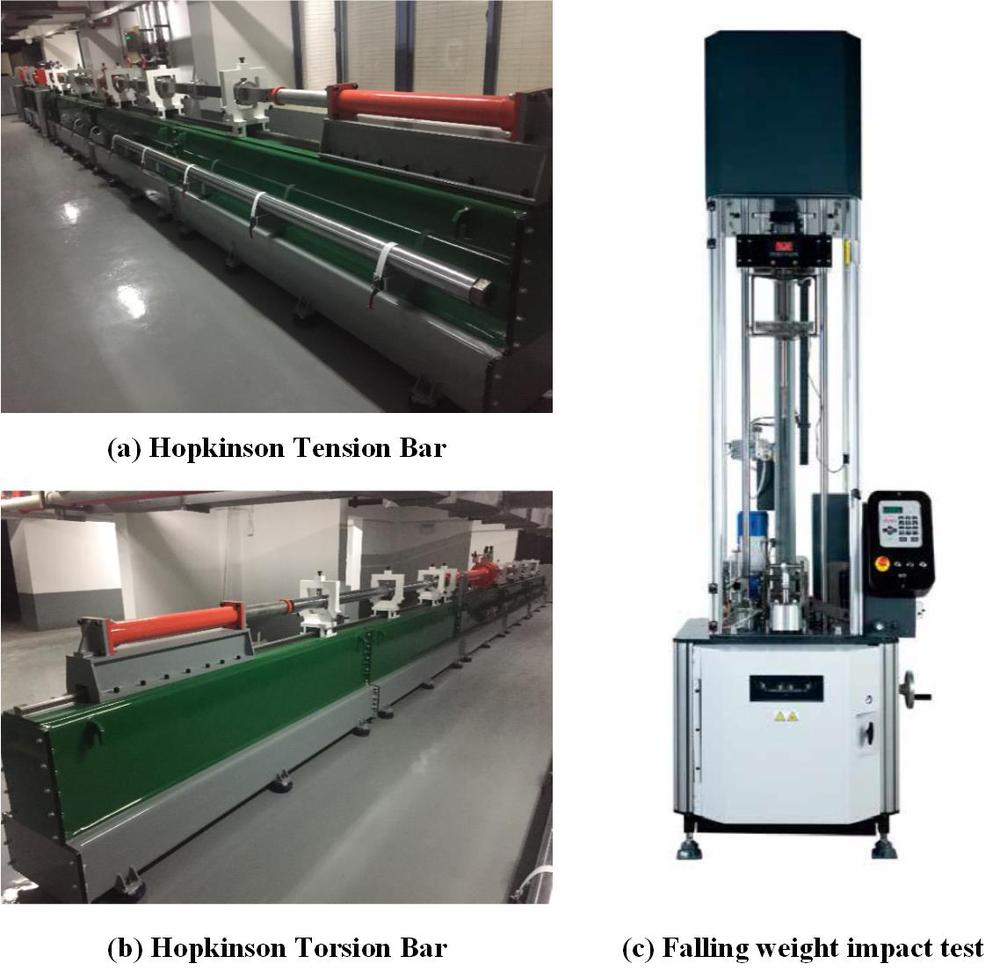

The opening equipment in laboratory includes the 6×9m three-way and six degree of freedom large-scale seismic simulation shaking table (see Fig. 1), unidirectional seismic simulation shaking table (Fig. 2), MTS hydraulic loading servo system (Fig.3), MTS 100 ton (Fig. 4) and 50 ton (Fig. 5) electro-hydraulic servo fatigue testing machine, Instron 25 ton electro-hydraulic servo fatigue testing machine (Fig. 6), 1700 ton compression shear testing machine (Fig.7), Hopkinson compression / torsion bar testing system (Fig. 8 a-b), Drop weight impact test system (Fig. 8 c), horizontal fire test furnace (Fig. 9), vertical fire test furnace (Fig. 10), 10m L-shaped reaction wall (Fig. 11), 15m L-shaped reaction wall (Fig. 12), 10t hydraulic servo fatigue test system and temperature control device (Fig. 13), hybrid test system, shaking table and actuator (Fig. 14), universal tensile testing machine and its temperature control device (Fig. 15), etc.

In addition, the joint laboratory also has vertical lifting test platform (Fig. 16), 10mW large calorimeter system (Fig. 17), building structure node fire resistance measurement device (Fig. 18) and other relevant test equipment.

Fig. 1 6 × 9m large earthquake simulation shaking table in joint laboratory

Fig. 2 6 × 9m large earthquake simulation shaking table in joint laboratory

Fig. 3 MTS hydraulic loading servo system

Fig. 4 MTS 100 ton electro-hydraulic servo fatigue testing machine

Fig. 5 MTS 50 ton electro-hydraulic servo fatigue testing machine

Fig. 6 Instron 25 ton electro-hydraulic servo fatigue testing machine

Fig. 7 1700 ton compression shear testing machine

Fig. 8 Hopkinson compression / torsion bar testing system

Fig. 9 Horizontal fire test furnace

Fig. 10 Vertical fire test furnace